Some of the owners of Xiaomi 4K mijia laser projector (or Wemax one, Fengmi, e.t.c) facing some problems in the operation of their projector that actually make the projection…nightmare.

What are these problems?

-The projector has slow boot, it can take 10 minutes from the moment we press the on button on the remote control

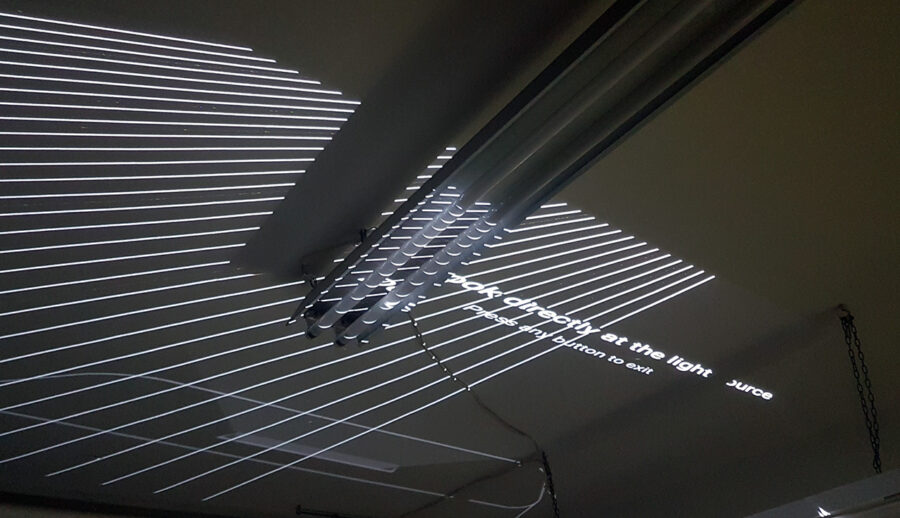

-After some time of viewing or immediately after opening in half of the image, white vertical lines are observed

-After some time of operation, white dots are observed in the image

-Random restarts

-Shutdowns

For all these problems the cause is one and only defective part..

An accessory to the optical engine that has a manufacturing error, let’s go to see in detail the problem and the solution starting with some basic instructions disassembly the projector.

The white lines look like this…

To remove the projector housing, we must first untie and remove the Ι/Ο card. Remove these two plastic pieces, unscrew the 2 screws we find underneath and remove the card

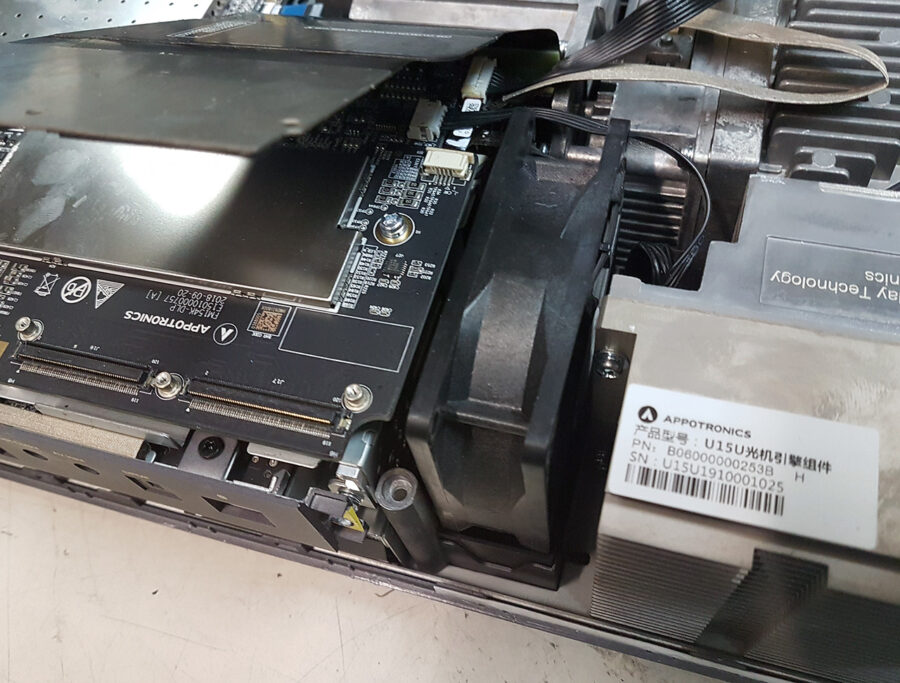

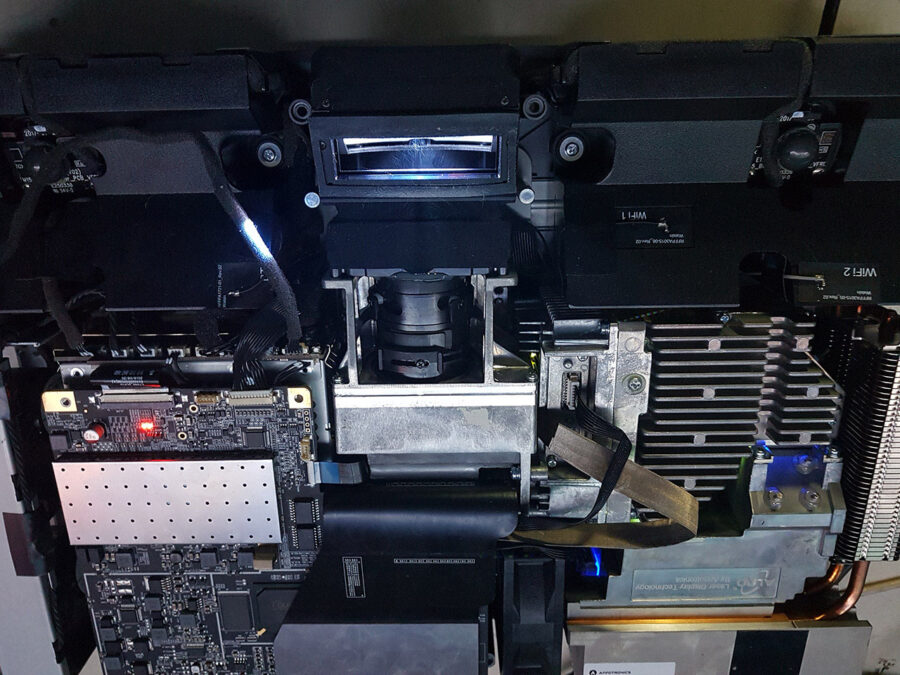

After unscrewing the screws at the bottom of the projector, we can remove the housing. As soon as we remove it, we’ll be in front of this picture…

Unscrew and remove the metal protection over the mainboard and begin to disconnect it from the various plugs that are buttoned to it with the first large cable that connects the optical engine to the mainboard. Three screws are the ones we need to unscrew and then carefully disconnect the cable.

Attention is needed to disconnect a few more flat cables that we will find connected on the mainboard

It should be removed and this fan, which is not screwed anywhere, we just grab it and remove it..

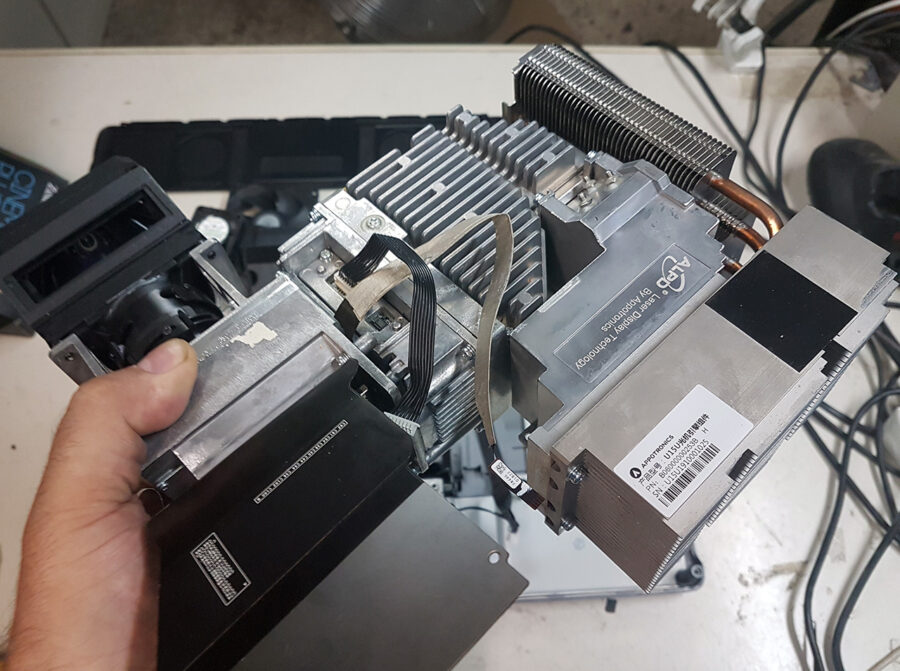

After we have removed the mainboard then we are ready to remove the optical unit. 4-5 screws are the ones that support it in the chassis, once we remove them we can remove it..

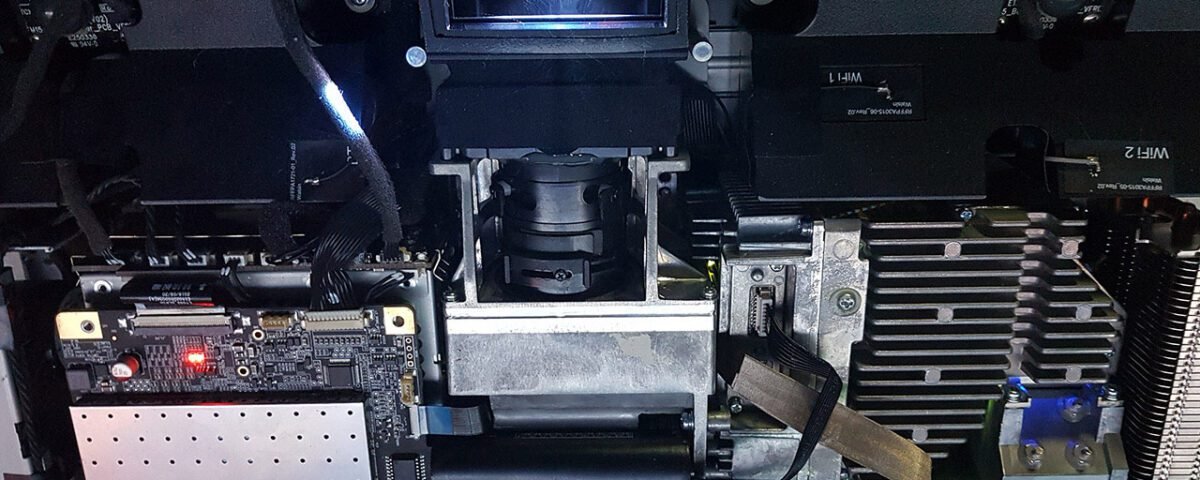

After we remove the optical unit, our projector will look like this.

The problem is on the optical engine, so will work on it…

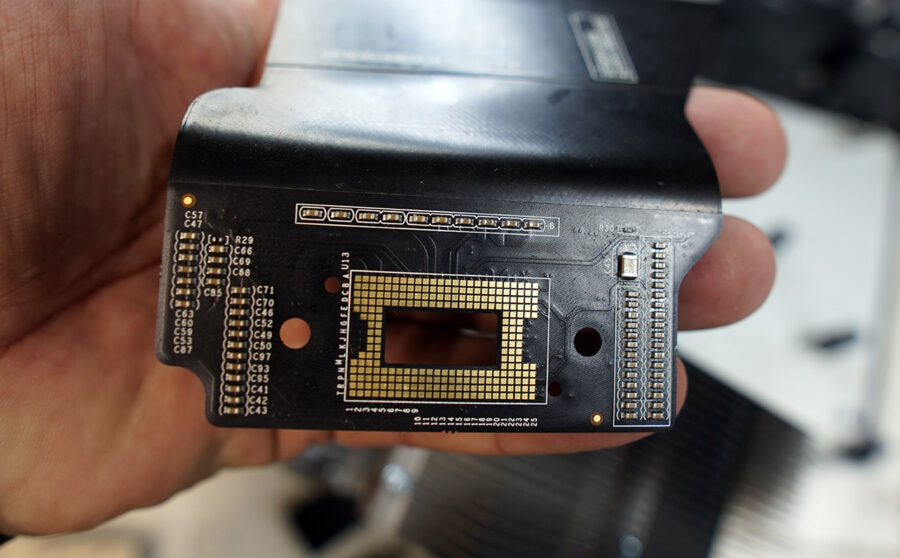

Next step is to unscrew the DMD Chip’s cooler…

Then carefully remove the two screws from the metal surface and remove the flat cable

This is the cable that makes it possible the communication between mainboard and DMD chip…

Here we can see the contact points

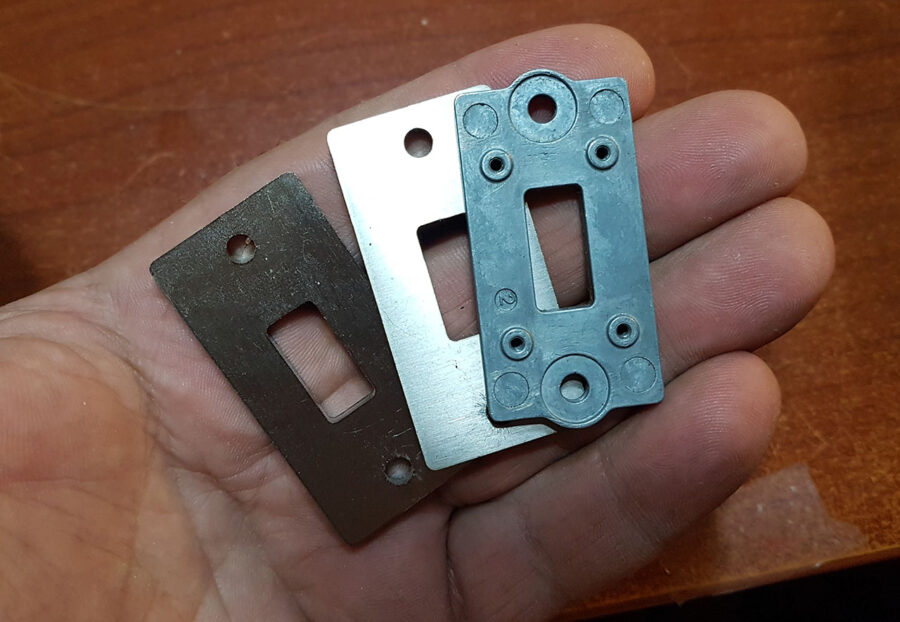

And we come to the source of evil, which is no other than this piece of metal that actually presses the flat cable to make proper contact with the DMD chip

But what’s going on, and how does this metal piece cause such a big problem in the projector?

This metal piece is a cast metal which shows little resistance to the high temperature conditions prevailing in the optical machine resulting in bending.

Yes well heard, bends and no longer presses evenly the flat cable on the DMD chip

If you look closely you will see the “curb” that has been created…

And here with graphics a little more understandable the alteration that has been suffered

This inflect does not only cause all these problems i have mentioned above, but it also create poor contact between DMD and the DMD cooler, so the chip is overheating. The overheating make the fans to spin with greater speed (so projector comes more loudly) or making our projector to shutdown. Finally there is a possibility to permanently damage the chip if we continue operate the projector.

The solution

I tried to solve it in many ways. At first I just bent this metal again and restored it to its original form. I tried it for a few hours on the projector but found that it started to lose its flat surface again and started to inflect again!

This time i realized that no solution can be found with the existing part. Even if I bought it new as a spare part, it would probably give the same malfunction in a few X hours.

So I started thinking about building a new one.

As a first step I made a copy in hand of brass (easily worked by hand) and tried it. In fact, I changed his shape and gave him larger dimensions where it took me to do it, so he could create a larger contact surface!

100% success!at the begining at least…

But I didn’t stay there. As a restless spirit I wanted to get to the end!

If the plate does not have exactly the right details and thickness on specific points it can cause other problems (DMD chip overheating, big pressure on the LGA250 DMD plastic socket, e.t.c)

So I proceeded to design the accessory and manufacture it in Laser CNC with experiments on metals and their strength (a new world opened up in front of my eyes and I dived in!).

So somehow I created a lot o f versions to try them but the results was not what i want and expect , some of them starting to inflect again like the original, other bend throw time just few mm and didn’t offer the perfect contact for the DMD i had in my mind…

So i finally after almost three months of testing and research i succeed to make the final version on a CNC laser with perfect accuracy on the thickness and the details. Also this plate is a mixture of metals based on stainless steel SS316 which with the addition of 2 more elements acquires incredible resistance to temperatures and pressures (we are talking about crazy research, running in machining and MANY tests to find this metal, but is worth it!). Maybe I’ve overreacted… but it was worth it, my xiaomi working 6-8 hours per day months now without any issue at all!

After a lot of tries this is the final version that i have made a lot of tests and works just perfectly …

The greatest satisfaction for a technician is when his efforts to find a solution to a problem come to fruition. And in the case of Xiaomi 4k laser projector, the satisfaction came, with VERY toil, but came.

The repair video

And a new video guide that many of you ask for, enjoy…

In case you experiencing this problems in your projector and you want to solve it permanently, you have to replace this part , you can manufacture it (but be sure about the CNC laser accuracy you going to use otherwise you will cause bigger problems on your projector!) or contact me (info@projectorjunkies.com) if you want to make and send you a copy of this final version of the plate. You will place it in your projector and you will solve this “factory” problem once and for all. Of course if you don’t feel capable το replace the part by yourself you can always send me your projector to repair it for you!Not a problem.

(My advise is that until you replace that plate DO NOT operate the projector, there is a possibility to damage the DMD chip with this poor contact, and this chip it is very difficult to find it as a spare part!)

UPDATE! (12/2020)

At the newer models (2020) Fengmi seems that have replace the metal plate with a new aluminum plate. It is better that the old one but…unfortunately it bend too enough to give poor contact again!!!I just repair a Fengmi 4K 2020 with bend aluminum plate!

This is just unbelievable. It tooks me only 2-3 months to experiment and finally find the correct material and make a plate that will never bend, and i am…. nobody! I want to believe that such big companies can make a really strong metal plate, or to find the permanently solution in few days or hours of research, but they don’t …what can i say…

UPDATE (11/2021)

The problem it seems that is solved on latest models. The new factory plates are tough enough and do not bend over time.

You can also read my full review of the Xiaomi 4K laser projector here https://projectorjunkies.com/xiaomi-4k-ust-projector-review/

And the XPR 4K technology explanation here https://projectorjunkies.com/4k-dlp-projectors-is-it-real-4k-xpr-technology-explanation/

Stay safe!

Nikos Tsolas

332 Comments

Amazing, my xiaomi is experiencing the same problem as yours, and mine one with the black lines as well..

Can I have the contact of the CNC store, please?

I would like to fix mine one, otherwise I will have to buy a new projector..

Regards

Jacky

Hey Nikos, how can I contact you? I would like to order the plate aswell!

Looking forward hearing from you!

Hi, I’m new here. I got my ust mijia since 2019. Now the system starting to prompt off high temperature.

Periodically will clean the dust internally. But I think the metal piece has starting to get warp, hence the high temperature prompt.

Is there anyway you can sell a piece too me to replace the original metal plate?

Hello,

Mine is taking a few minutes before turning on. I hope that this new piece will correct this issue. Thank you for your work. I am interest in this new piece of metal. How can I please get it ?

Best regards

Ary

Hello Ary

Have you found the right metal for the part?

I just disassembled the projector and getting the measurements, and I will build a CAD based on it. But still looking for the right metal to use, I saw Nikos is using ss316 but I wonder if it is suitable for transferring the heat as well.

Regards

Jacky

Hi Jacky,

Did you manage to build the CAD file?

Best,

Bob

Yes, I drew one, and looking for a CNC machining company.

Would you mind sharing the file? I found a company here during my holiday but I don’t have the projector with me to copy the piece. Happy to share the info about their suggestions regarding the material after the visit.

I am happy to share it, but I am not sure if the piece fit to the projector, and I do not want others using the wrong measurement. I found one company, and they can cut and ship me the piece in 20 days. I will definitely let you know further.

From my experience is very difficult to copy this plate. In the start i said, ok,it is just metal, not big deal, right?no no no, it is a big deal. If you don’t make all the details exactly as they are, it does not fit and the DMD cooler can not fit as well. I try three different CNC lasers and i have make more than 10 plates in order to finally make the one.

The CNC lasers can not stop the production and spend time to make one or two pieces with so much details, they drop you.To just cut the metal is very cheap and easy, but this is not the point (something like 2-3 euro per piece), to design and make the details is that CNC does not accept to do it, and if someone accept, the cost goes high at 80-100 euro per piece (the better price i take was 80 euro each for 50 pieces).

The other problem is the metal, i try 3-4 different well known metals that the CNC work with mostly, and ALL inflect after 30-40 hours of use only (not at the point to start the problems,not so much like the factory one, but i knew that this was not the permanently solution i was looking for), even the strongest one.

Of course when i return every time to the CNC store to say about the metal is not so strong as they said to me, they always told me that they are not responsible for the use i will do on this metal piece and i paid again for the new one.

If you have a thin metal plate under pressure in the heat it will inflect at the end, even least, i didn’t know that, i have learn now.

If it is inflect even a half millimetre (you can not see it by naked eye, every time i put it out from the projector and go to the CNC store to measure it) it will cause problems like delay start at the beginning and bigger issues at the future.

For me to finally find the CNC laser with the most accuracy on the details and the patience το deal with, the right metal with the correct aids on the spots i have pointed out, to find out that you have to make the plate a little bigger than the original because the final procedure (that i am doing to a different machine shop that is specialized on that), the shine (you can not push the flat cable with a non absolutely shine metal, you are going to make a damage), does effect on the final fat of the plate (oh yeah) and you must have already calculated it (if not,the plate will not fit correctly, trust me, i HAVE PAID this), all this cost me more than 1000 euro and over 3 months of time and tests.

Right know all these details is on my CNC laser guy (and the special mix SS136 metal that i buy it from a specialized metal store here in Greece, this week i am going to buy more and i will inform you guys what exactly is the mix) and the shine specialized store and i am just call and ask them to make me a copy. At the moment i am waiting 10 more copys next week because i have already 5-6 requests from people all over the world ask me to send them one.

I am very curious what will be your story guys if you try to make a copy of this plate to your local CNC laser store, and if you finally succeed to do it how this plate will behave throw time and heat on your projector. If you want, please share it here, it will be very interesting…

Thank you for sharing the process with us, Nikos, it is very interesting and challenging. For finish of the metal, I never thought about it has to be shine finish, no wonder the original one has the plastic sticking on the back. Yes, I believe it is no easy to copy the exact same one, even I drew a CAD for the piece, I am still not sure about measurement.

Please let me know how can I order one from you.

Many Thanks

i always share my repairing procedures on my blog Jacky. If you want to send you a copy of the plate just email me your shipping details.

Hi Nikos,

Im having the same issue.

How much do you charge for making the metal plate for me?

Hi Nikos and all

My projector wemax one pro cannot power on anymore…

Any guess?

One repairman said it should come from the motherboard…

Thanks in advance everyone.

Take care

Henri

Hello there,

My Xiaomi 4k 1s boot but there is no light (even intil 10min and more).

It is the same problem ?

Best regards

hello

same problem for me do you solve your problem ? thx

Hi Nikos,

I would like to purchase this metal plate!

Could you send it to Switzerland?

I look forward to your email.

Kind regards,

Reto

Hi Jacky,

Woaw. Sorry. But I am not as qualified as you 😉

I didn’t disassemble it yet. And I am expecting Nikos to help me find and buy this piece of metal. Then the Next stage will be to mount it.

But really, I am interested if you manage to do it by yourself. Happy to share your experience

Regards

Ary

Hi guys,

The same here.

Once I left it running overnight, normally it goes to sleep but that time it didn’t.

Next day boot time degraded, then it started degrading more. then some artefacts started appearing. Boot time went up to 10 min or more (not the actual boot time but the time it needed to start throwing the picture).

I found there is another issue with this projector. (another data cable). That kind of worked- boot time reverted to normal but more white dots appeared over time.

So I hope Nikos would be able to help here.

Please see workaround for another design flaw posted by user ‘huntereye’

https://www.avforums.com/threads/xiaomi-4k-laser-projector-review-now-with-videos.2231266/page-15#post-27801955

==

hi, I believe issues such as white pixels, distorted color and slow starting were all caused by the same issue, which was a design flaw of the data ribbons near the center of the projector. I ran into these problems 6 months after I bought the projector. I managed to fixed the Xiaomi 4k projector problem recently by opening the cover and grind the plastic ridges off at the back of the cover (see pictures attached), the ridges put too much pressure at the grey data ribbon near the center of the projector hence causing the image problem.

==

it’s worth mentioning IO card removal trick – you should press the center as it is thinner and you would be able to pry this piece easier.

Regards,

Vad

The design of the ribbon cable is just fine. The cause is this metal that holds the ribbon cable (read my article). This is the reason, not the ribbon cable.

Hello Tsolas

I was able to flatten the metal, it is ok for now.

Could you share the CNC store and the material you used to replace it?

Many Thanks for sharing

That’nice.The problem is that in few hours (100-200) the metal will inflect again (from the first 2-3 hours i measured a small bend again already), that’s why i try to find another solution with another metal part. The CNC laser is in Greece, the metal part after trying different materials is a SS316 with other two elements inside (i don’t know them, i can ask the CNC store, they suggest that metal). This is the only metal that we measured no bend at all after some hours of heat.

Thank you. It will be great if you can let me know the name or code of the metal. It is great that you are a restless spirit so my projector can be fixed!

Do you know how different is it from the ss316?

I know ss316 and ss304 are easy to access in US.

let me ask for this and i will come back to you!

Hello I am facing the same problem in my projector so CAN I please give me the metal part?? I will be very grateful to u

Hi. Do you have the measure of the part you have made?

Hight, width, thickness, mm for screws etc.

Hi, I’m new here. I got my ust mijia since 2019. Now the system starting to prompt off high temperature.

Periodically will clean the dust internally. But I think the metal piece has starting to get warp, hence the high temperature prompt.

Is there anyway you can sell a piece too me to replace the original metal plate?

Hello, we are having similar issues with the whore vertical lines, how would we go about getting the piece shipped over here so we can get it fixed?

Thanks!

Hi Nikos, I’m having the same issue, how can I purchase the part. How soon would it be possible to ship the item and how much will it be (location Melbourne, Australia). Thanks, Pratik.

hi, i live in france and i need a plate like yours.

how can i have one ?

thanks arnaud

Good evening Nikos, i have read your blog with pleasure. My Xiaomi mijia S is also suffering from one white pixel since one week. I expect more to follow…can you please provide me with a spare plate? Many Thanx in advance

Do 100% projectors have this problem? If not, what is the difference between them? What is the difference between them?

Dear Nikos,

I’m facing the same problems with my 4K projector after 9 months after buying.

Do I need special tools for demounting all the parts? what will you charge if I want to buy the replacement part?

Looking forward to your reply.

i have send you an email with the details

Hi, Nikos.

Thank you for your work. I wrote an email to info@projectorjunkies.com a couple days ago, but I didn’t get a response. Maybe it went into spam ♂️ I’d like to buy a replacement part from you, could you mail me please.

hello, i have reply to your email

Hi Nikos, i have sent you one email today for a different problem, can you pls check if you have rcvd. I sent from ahluwaliakulpreet@gmail

HI DEAR HOW ARE YOU

I NEED your help to find MAIN BOARD FOR

XMJGTYDS01FM 4K Laser projector

FM154K-DLP

E15010000757

Hi Nikos I’m having the same issue will the lines how can I purchase the part. I’m in Bangladesh how soon would it be possible to ship the item and how much will it be I Also need a another part can I call you can I have your number. Thanks Johnny

Please email me johnny815ca@gmail.com

Dear Nikos,

Thanks for your amazing post. On the problem of this Projector. I was hunting for the same in the last two weeks

I have seen your full video on the repair of the Projector by replacing the plate.

My Projector when switched on gives lines and dots and no picture. I am sure it the same problem of the plate, would you be able to make one for me and despatch the same by DHL? What will be the cost? How does one pay for the same?

Kindly guide and help on this as the Projector is only one year old.

SOS

Cheers

Cdr SK Naresh

Hello Nikos, can you send me the information on how to order the replacement metal plate for my xiaomi 4k projector. I am having the long boot up time issues.

Gary

Hi

How much this part with shipping to Poland ?

Do you have STL file or other 3d model..?

Best regards

Hi Nikos!!

I have exactly the same problem. I would like to buy the metal part from you! I can we proceed?

Hi.

I am Having the same problem. I sent you an email. I would like to buy this metal part from you. 🙂

Hi Nikos! I have the same problem with my Xiaomi 4k cinema. I disassembled projector, find out curved piece of metal and made my own. But problems didn’t disappear. Then I disassembled it again and looked at the pinned plastic between chip and cable. Some pins were bent. I corrected them in the right place, but the second approach also had no effect. Now I plan to take out plastic and correct all pins, cause I have no other ideas. I’ll post here the results and can send you some photos of the process to your e-mail if you share it to me.

Regards, Mike.

Mike can you send me photo of the metal plate you have made?Μy email is on contact page. I ask you because the first 3-4 plates i made didn’t work.It took me a lot of time to find the CNC laser that was able to make the exactly copy of the original. Also have you measure the plate again after the polishing process?Because it loose a lot of micrometers on the procedure and this could cause problem on the DMD contact. If the dimensions on the plate details are not exactly precise then even if you tight the screws and everything seems ok, the pressure on the ribbon cable is not the one that it should and the contact on the DMD is not the ideal, so the problem remain (keep in mind that on this optical unit everything expand and shrink with the heat), also if the pressure is bigger you can destroy the socket and damage the pins (this is i suppose happen to you).Anyway you can search and find this socket and buy it if you have destroy it, it is a LGA250 dmd socket (google it). Also the material of the plate must not affected by the heat. If you have a micrometer try to heat the plate you made well and take measurements to see the metal behavior.As i have already say it seem too easy to make a copy of the plate and replace the original, but is not!I have learn this on the hard way…

Thanks a lot for the quick response! As promised, posting here news from my further investigation:

1. First of all I restored the original plate and put it back in place. This allowed me to temporarily exclude the factors that you wrote about. The result is that the vertical lines have not disappeared.

2. Then I carefully examined the nature of the vertical lines and found that they carry color. Moreover, they inherit color from each previous line to the left. This means that the contacts on DMD are not broken and the plate in my case works as designed.

3. Then I went to the engineering menu in projector and ran a series of tests. The most spectacular are black lines on a white screen.

4. Also I measured the tempreture of DMD chip in a working state – it was around 40 C – not so hot as I thought before.

So: the symptoms are similar only at first glance: instead of white lines, there is a mixing on the X axis. It seems that the problem is with the video card.

Not having the proper tools, I took projector to the service center. I look forward to the results tomorrow.

Photos I’ll send to info@projectorjunkies.com in a few hours.

Mike i have seen your pictures.Oh man,what have you done there??First of all the plate you made does not have the details that must have in order for the cooler to contact properly on the chip, is not only about thickness! Second you are not using the original screws with the stop they have on plate (probably you couldn’t make such a small screw thread on the plate and you make them bigger?). What can i say, good luck my friend but for me, you have cause all these problems, probably you have damage the chip too (you dont even have a thermal pad to the back of the chip!). May i ask why you make all these modifications and repairs to that poor projector??The only problem you had on the beginning was the inflect plate i describe to my repair, nothing else.

Let me explain some points:

1. Yes, indeed, the plate I made is different from the original. Is it problem? Yes and no. As I said above, with this plate it works like a restored original. The result is the same: nothing changes. You may doubt this, but it is a fact. I’ll be happy to be wrong about that. But now I do not use it any more. An ok, the screws for that plate were mine, as long as the original ones. So the cooling pressure was the same.

3. Thermal pad is present of cause – I replace it with a thermoplastic with better thermal conductivity. This step is required because you cannot reuse an old one.

Note again: I have restored the original plate and install it with the original screws. The termal pad exists, the contact is just as good, I measured the temperature of the chip, it was about 40 C. And result is the same, as you can see on photos.

Now I’m waiting for the results of the service. I’ll post them here.

Mike what can i say?yes, it is problem if you don’t make the details on the two screws on the plate. The screws stay out and the cooler can not make good contact to the chip, you can burn the chip even with few minutes of not properly cooling, then you will wonder what happen. However, good luck with your repair, keep us infromed.

Hi, I have exactly the same issue: color lines on a half of the screen, new version with non-banging plate. I triple checked DMD, socket and ribbon. I think that it is a problem with motherboard, did someone try to order new one?

Hi. Do you have the measure of the part you have made?

Hight, width, thickness, mm for screws etc.

Yes I do. Really the size is wrong but in a previous comment I’ve describe some new investigations that let me suggest the video card problem.

Is the screws on the cooler UNC, UNF?

Hi Nikos,

I have sent you an email requesting the quote for the metal piece. Can you please reply ?

Hi Nikos and all the brilliant minds in this thread. Nikos, my projector case is in rough conditions after me trying to take it apart over the last few months and not figuring out about the IO card. None of the forums mention that, I appreciate you posting clear pictures. Than you.

That said, it’s functional, after it heats up I’m able to wiggle the case to the point there are no lines but I’d like to fix it before I’m tempted to bu another one. I’d love to send it and have you repair it for me, would that be possible? (Happy to pay of course)

thank you Roberto, sure you can send it to repair it for you, you are living in Europe i suppose. Send me an email to arrange that.

Hi. Thanks so much for sharing your knowledge. I tried to contact with you with not luck. I’m interested in the famous piece. Please contact me by mail if possible.

hi I can acknowledge the white pixel problem was not from the ribbon cable, I have tried loosen the projector case by unscrewing all the screws (to relief some pressure), it improves the slow boot problem a little bit but the problem is still there. So i guess ultimately the metal plate that is holding the DLP chip needs to be replaced.

Every time when my projector starts up, it will give the white pixel dots problem, and if I wait for a min or two the projector image will come back to normal, I suspect it was because the metal plate was heated up and expands, then the DLP chip can have proper contact with the ribbon cable.

yes Kevin, your porblem is this plate. If you want my advice DO NOT play the projector until you replace that plate if you dont want to damage the DMD chip.

After i straighten the bend metal part, my picture is gone very dark. 🙁

Paal how exactly you straighten the plate?By your eye?It have to be perfectly straight. If your picture is dark that can be a wrong seat of the DMD.

I have now made a exact copy of your plate of the steel that you use. The projector works perfect, the stripes are gone and the startup time is as new.

All thanks and credits to Nikos for sharing all his work around this.

Use Nikos if you are affraid for doing this yourself. Or if you buy his plate, be carefull with the contactplate between the dlp and the cable where the problem is.

Thanks Nikos, Great work.

my pleasure Paal!i am happy that you finally fix your projector!enjoy!

Hello Nikos,

I would like to have 2 of your Master Pieces 😀

Where can i find your email to get Futter information ? Or could you please contact me ?

Is there any model type that does not have these issues? Or do all models have this issue?

Hi Nikos,

I would like to purchase this metal plate!

Could you send it to Germany ?

I look forward to your email.

Kind regards,

Reto

I am interested in the plate. How do I go on about receiving one Nikos?! Mine have started flickering and wouldn’t turn on until you attempt to turn it on like 5-10 times.

Tsolas Nikos

Are you selling that plate?

Hello, if you want to send you a copy just send me an email with the details.

Hi I am intersted to buy 2 units of metal replacement part from you.

What is the cost with post to Poland.

Let me know.

Hi guys,

did sent my projector from Germany to Greece and got i back today – bootuptime now is as it was when its was brand-new from the factory. Nikos is a super nice guy, communication went really well!

Thank you Stephan, the pleasure was mine!

Hi Nikos,

I want to purchase this plate!

How much does it cost to send to Japan?

I look forward to your email.

Hello, I am interested in that Projektor too. The 4k1s i would take.

Is that issued with all of that Prjojectors?

@Niko: If I will get mine, how can i test If that issue is with this Projector? And If i have the issue can i send i to greece too?

When that metal starting to inflect you going to have slow boot and some times white vertical stripes on the picture.On that point you have to replace this plate. Yes, you can send it to me when the time comes to repair it for you.

Hello Tsolas.

I have the same problem in my projector. Maybe you have more of these parts? I would gladly buy 1 piece from you.

What would be the cost with shipping to Poland?

Hi Nikos, I like to thank you for this excellent solution. I had already declared my Xiaomi projector almost dead before I came across this web page. Rather painful considering it price back then and knowing I only owned it for just over 1 year. Anyway, the shipment of your metal plate went incredibly fast. Your prompt response to inquiries and friendly communication ensure that I recommend your help to anyone with this projector and its design flaw.

My projector works again if its brand new. Very happy with it and that I came across the projector-genius of the internet;-)

That is wonderful news Roel. Thank you! I am happy that you can enjoy your projector again!

Hi Nikos, Im from Malaysia, im really interested in buying this metal plate. can i get a quote, i really want my projector working as long a possible.

Hi, do you able to get the metal plate from Nikos?

Hi Nikos,

just sent you an email regarding the metal plate.

Hi Nikos,

ive got the issue that my projector is turning off after 11 minutes of running with some chinese message.

After turning it on again its working for hours without problems.

Is this also caused of this metal part or is it something else? Maybe you know it.

Thank you for your help in advance.

Grettings Andi

Hello Andi. Yes, it is possible the problem be this poor DMD contact. But have you ever try to translate this chinese message?

Hey Nikos,

thanks for your answer.

I googled it (cause my chinese isnt that well) and it seems like there are other people with the same problem after 11 minutes. It seems like its an temperature warning and then it shuts down to avoid damage.

But like i wrote before after turning it on again, it runs like forever. There is nothing placed around it for at least 2 metres around so i dont know what to do. Why should it get to hot? I am still in the 1 year waranty time, but its real a struggle with gearbest to get any help. They told me to press the reset button on the side, but there isnt one.

Also they said it cant be repaired and offered me 100$ and thats a joke.

Its really a shame how they deal with customers and warranty issues.

If i wont get any help of them i am forced to open it and install your piece of metal, if you are willing to send me one. Ofc i will pay for it. I keep you updated, if i got any news.

Thank you very much in advance.

Grettings Andi

When this plate inflect,it does not only cause poor contact and lines on the screen. It does cause poor contact between DMD and the cooler. So , it is possible the DMD to overheating and the projector to shut down. If i was you, i would start by replacing this plate.

Hi,

I had the same issue as you are. Do you have an external video source connected? And does the projector automatically switch to this at startup? If you answer yes to both above then you could be seeing the auto shutdown message in Chinese (shutdown where there’s no response). There’s a menu option under settings to turn this feature off. (Use google translate on your phone to see this screen because even with English language selected this menu item remains in Chinese). Then turn the auto-shutdown when no response off.

Nikos, my projector is displaying a black screen with some white dots. Do you think it will cause due the same problem?

possible!

@Andi, this sounds like you are starting the projector from the power plug (e.g. plugin it in or using a remote smart plug) not the remote. The message you see it telling you (paraphrasing) that the projector will shutdown in 5 seconds, press any key to cancel. It is a safety mechanism to turn the projector off after loss of power / return of power etc. It’s the same with my 4k Chinese version, may effect any of these projectors that don’t have a power button on the unit.

Matt

Hey matt,

thanks for you answer. You are right. I am using a switchable power strip to turn the projector and devices totaly off. That are good news for me. The internet told me until your answer that this is an overheating issue. I am very glad that isnt the case. Thank you very much for your help.

The only strang thing is, i am almost sure, i havent had that message in the beginning when i started to use it.

Greetings Andi

hi Nikos. I’m from Russia. You have no idea how difficult it is to find at least some information. A friend of mine from China sent me this masterpiece half a year ago (the projector is exactly the same as yours). This disease has appeared last month. I wait about 10 minutes with a black screen, then everything is fine. As soon as I found you I stopped using the projector. The seller ignores the buyer, they gave some kind of code that is valid for 30 days, and I did not have time to send it back, then all service requests and advice were refused. This is the first time I come across such hypocrisy and irresponsibility on the part of my beloved company. I want to join the lucky ones you helped. Please contact me by email to clarify the purchase of your miracle plate. Even if this does not solve my problem, I am infinitely grateful to people like you who help.

Hi, I too would like to purchase one of these magic pieces, thanks!

HI I would also like to purchase one of the magic metal pieces.

Out of curiosity, I haven’t opened it up yet, but would thermal paste on the non cable side help transfer heat to the heat sync and reduce the issue? Are there fans in the case that could be upgraded to higher cfm?

The answer on both is no. The projector temperature it is just fine if you change the plate, there is no need for any modification!

niklos, I’m facing this same problem: random shutdowns. I’ve Tried everything, but nothing has worked so far. I’ve tore down the projector and find nothing wrong. So, I think That this piece of Plate of yours can solve my Problems. I’d like to Buy it from you or get the project to do myself.

Greets

Hello Nikos,

First of all, thank you for doing this and helping so many people, I really appreciate it.

I also have exactly the same problem as everyone else, 3 minutes boot time and the stripes on the screen that dissappear after 30 seconds.

I would like to buy the plate from you if you still sell it

Than you.

Dear Nikos,

I am having similar issues with my wemax one. I’ve already sent an email too. Can I buy one of your plates?

Thanks

Shaminda.

Hi Nikos, I finished placing the piece right now with the help of my son and I also put a little thermal paste and after assembling the whole projector it returned to normal, without the vertical lines and now starts as when it was new.

Thank you for all your work and for sharing all this information and also for selling and for sending the piece to Spain. I was very discouraged with my Wemax 4K projector and now it’s new again. Thank you very much.

Best regards,

Jorge Moreno

Τhat is good news Jorge!enjoy your projector!

Hey Nikos,

thank you for this excellent guide and work you spent on it! I would be happy if you would reach out to me, as I would also like to order one of these plates 🙂

Thanks and greetings,

Andy!

Hi Nikos,

I have similar problem with my projector.

How do I go about getting one of the plates you mentioned on the platform?

Please, reply as soon as possible.

Thanks.

Hello Nikos,

I’ve sometime these issue :

– white dot on black screen

– wrong colors on the screen (purple,…)

– it makes time to switch on the screen

I think the issue is the plate.

I want to buy one of you, is it possible ?

Thank you very much for you helo and time !

Hi Nikos,

I have similar problem with my projector.

Slow start, white pixel appearing,

wrong colors on the screen (purple,…)

How do I go about getting one of the plates you mentioned on the platform?

Please, reply as soon as possible.

Thank you very much for your help,

hi NIkos,

First of all, thank you so much for this tutorial. Very helpful.

I have sent you an email re the plate. Hope you can help.

Much appreciated.

Ethan

Hi Nikos

I don’t have the white lines but the startup is slow and sometimes the colors are distorted. first i opened the case a little bit and it helped for some time but now this isn’t working anymore and the startup is slow again. should i do what’s mentioned here or is this only the metal plate? would you repair it when i send it to greece? or could you send me such a plate?

regards, nicolas

It is the metal plate. I also came across this article also before I bought the plate. If this would have been the root cause I wouldn’t have a perfect working projector now:-)

Bonjour Roel,

Vous avez achetez la plaque métallique de Nikos et vous avez fais le changement vous même ?

Pouvez vous donnez vos impression après le changement ?

Cordialement,

Hello Roel,

Did you buy the Nikos metal plate and change it yourself?

Can you give your impression after the change?

Regards,

Hi there, a friend of mine changed it, but Nikos gave prompt instructions along the way (because the step by step manual was not always clear enough).

My impression is that my projector works again as if it is brand new. I use it daily since the repair (on Sept.19th).

Highly recommended

Bonjour bulldog16,

L’as tu finalement acheté ? Si oui, Comment s’est passé l’installation ?

D’avance merci pour tes reponses

A bientôt

Ary

I see in your test of the vividstorm screen that you are using the Xiaomi 1S 4k do you know if this model also suffer from this plate issue ?

Hi Nikos,

Please let me know how to order a plate from you. I’ve sent you an email and hope to get a response very soon. Thanks!

Hi Nikos,

I’m not comfortable doing the repair myself. Would it be possible to ship my projector to you and you repair it with your part? If you have the time I’d love to discuss 🙂 Please send me an email!

Hi Nikos,

Thank you for doing the research for the fix.

Happy to do the repair myself but need the plate. Please let me know how to order it from you.

Best,

Ricky

Hi Nikos,

Thank you for your R&D and find a fix

Please let me know how can i order it

Regards

Titi

After more than 1.5 of wait in shipping to USA, finally the magic plate arrived today. The repair is done just under an hour. The projector is working like new again !!! Thank you Nikos.

Hello Sambeet. How hard did you find the repair ? Do you think the average guy with some tech experience could do this?

Its not hard at all. I would say, the hardest part is taking the cover out. After that, follow the pictures given by Nikos. Remove the off-white tape gently and save it to re-apply later. There are few cable connectors attached to the main board. Be careful with one ribbon cable connectors on the right side/next to the fan. Its is bit flimsy. Lift the white tab to release the cable. Then take the main board out. Then take out the whole optical engine by releasing 6-7 screws attached to the bottom of the case. Then remove the heat sink followed by Old Plate.

Hey, Nikos! I got the same problem on my Wemax One…Do you sell one of those plates?

thanks,

Carlos Valdes

Hi Carlos,

I have a Wemax One. Had a auto shutdown issue. Turns out Wemax doesn’t have a similar plate. Ours has a smaller ribbon. The plate also has rubber paddings to push the connectors down.

Hello Nikos,

I sent you an email. I would like to buy this metal part from you.

Thank you

Hello Nikos,

I’d like to order a part as well please! I’ve sent an email.

Thanks

Calum

Hi – just following up – very keen to get the part from you

Nikos hello,

in my place with this problem, a long turn on, another one arose, a slightly visible gray border appeared and there were 2 small strokes of light on it (I had not seen this border before, it got out after the next system update, this also coincided with a long start). Although many people assure me that this border is always there, now it looks like scratches have appeared on it (it seems that these are not pixels, since it immediately lights up, the pixels start much later.

I still have a few pictures before the problems and as if I do not see this border at all, it feels like you can shift the initial position of the optics and do some kind of calibration, as if the optics were corrected before the system was updated and after the correction had disappeared.

I saw another person on another forum with very similar scratches on the border of this frame. We don’t know what to do about it.

there are 2 pictures before and after frames

Nikos hello, in my place with this problem, a long turn on, another one arose, a slightly visible gray border appeared and there were 2 small strokes of light on it (I had not seen this border before, it got out after the next system update, this also coincided with a long start). Although many people assure me that this border is always there, now it looks like scratches have appeared on it (it seems that these are not pixels, since it immediately lights up, the pixels start much later. I still have a few pictures before the problems and as if I do not see this border at all, it feels like you can shift the initial position of the optics and do some kind of calibration, as if the optics were corrected before the system was updated and after the correction had disappeared. I saw another person on another forum with very similar scratches on the border of this frame. We don’t know what to do about it.

there are 2 pictures before and after frames

Hey Nikos, how can I contact you? I would like to order the plate aswell!

Looking forward hearing from you!

I would like to order the part too.

Hi Nikos, how do I place order for the part, having the same issue. Thank You.

Hi Nikos,

I’d like to order a part as well please! I’ve sent an email.

Thanks

Hello Nikos Thank you very much for this video and all the work you have done for the repair of the Xiaomi 4K video projector MJJGTYDS01FM and for the new Plate that you have created in laser numerical control with the details of the holes to tap frankly me who am a manufacturer of job I appreciate the work you did,

I need to purchase this part from you. Please help. My projector is a disaster.

Hello Nikos,

I have had the Xiaomi Mijia 4K Projector for a year, I have noticed its longer startup for 1.5 months. From the information that I read earlier on the internet and on your blog, it appears that this is the beginning of the problem you described here. I am interested in buying this part from you, I will be grateful for contact and help with the problem.

Regards and I hope for an answer

Hello Nikos,

I have just received my license plate, I have repaired, luckily there is a video, it makes it easier to dismantle,

Before repair I had slow starts getting longer and longer and two pixels on white backgrounds not on black backgrounds not all made in the middle of the screen,

After repairing no more problem all works fast start and more pixels for the moment to see in time my now we know where the problem came from,

Many thanks to Nikos for his help and his patient,

That is good news!Enjoy your projector my friend!

Hello, could you please send me the link to the video. I have received Nikos new plate and i would like to set it up .

Many thanks

Thanks Nikos,

I repaired my projector, I made a copy of the original plate, and re-pasted the sticker (sticker 0.2mm thick).

4 cylinders on the plate play a role for the correct distance of the bolts with the springs, I made them just in case.

Drawings and models, if useful to someone, can be found here:

Thank you Sergei!If you want to make an improvement to your plate, cut off the 4 cylinders. The thickness of the plate alone is enough for the screws to screw tight without pass throw to the other side, so it is safe. Also without these cylinders the compression of the springs is a little bigger and the cooler is make better contact on the thermal pad on the chip.This will help you to not have any dead pixel in the future, trust me. Another improve is to NOT put the plastic sticker just make the plate a little bigger. The reason is that this plastic is not heat conductive so if you just make contact the metallic plate on the flat cable without it (but you must have polish the plate realy well, to be perfect flat) you help the heat dissipation from the flat cable and from the chip of course, something like second cooler.If you do that you will realize that the small fan on the DMD cooler is more quiet and does not run at maximum speed after 20 minutes of running the projector (check it to see that i am right),also the temperature on the plate will be a little higher, that means that the chip is running cooler. Good work and thank you for sharing!

Thanks for the clarification Nikos, I will try to remove those bosses.

And are there any ideas how you can remove my second problem 2 lines of light around the edges

This little screw cannot be responsible for the basic setting of the optics, I have a trace as if it had previously stood to the right (I did not touch it), it’s difficult to suggest that the motors moved it themselves). Or I somehow got scratches on the curb, I also remembered that this problem got out when I reset the projector to basic settings through the menu.

I will be glad to any suggestions and ideas)

“and re-pasted the sticker (sticker 0.2mm thick)”

Do you mean thermal paste ?

No, not thermal grease tore off the sticker from the original plate and re-glued it (it seems to me that it is glued for better sliding when pressed)

Hello. I am interested in purchasing the new plate. Are they about? Thank you.

Xiaomi wanted to charge close to 1,000 Euros to replace the whole optical unit here in China, as my one year warranty had ended. Nikos replied immediately and sent me a replacement plate via a tracked postal service, it took 20 days to arrive. Once it did I followed the steps outlined above and it solved my vertical white lines issue at a small fraction of the price. I was hesitant, as I don’t normally take electronics apart, but the steps were clear and photographs really helped. I did count 7 screws holding the optical unit in place, a few more than mentioned above. Thanks again Nikos.

Received Nikos’ plate today and installed it right away.

Easy to install and a perfect fix!

Used to take up to 10 minutes for the projector to show an image, now after the fix it is like the first time i turned it on, an image right away!

Thanks Nikos for finding the problem and offering the solution aswell!

Hey Nikos, how can I contact you? I would like to order the plate aswell!

Looking forward hearing from you!

This is the correct fix!!!

I received my plate from Nikos last week and installed it right away. I took an hour to pull everything part and put it all together.

My projector went from taking 10 – 15 minutes to turn on to about 5 seconds now. No problems with lines and color issue now.

The part was shipped from Greece to US Northern California so it took about 10 days to arrive.

Thank you Nikos for your amazing engineering skills and knowledge!!

I have been looking through the guides, and im wondering if you should replace the thermal compound on the chip with something like thermal compound for a pc cpu for better conductivity?

I would like to order the plate if you could contact me.Thanks.

Hello Nikos,

I got exactly the same problem with my Mijia.

I would like to order a plate from you. Can you please contact me in order to arrange the details?

Thank you so much, amazing job!!

Hello Nikos,

I think you will be my big saver with this solution 🙂

Thank you for that in advance.

How can I order this part from you

Best regards

my ribbon cable is broken, I can’t find it anywhere. Can someone tell me where you can buy it?

Send me a photo of the cable to my email please.

Hello, do you know if this plate problem has been corrected on the xiaomi 4k 1s?

Unfortunately no. The 1S has the same issue.

I received the plate yesterday and installed it immediatelly.

No more Problems. White lines are gone and projector now shows a picture right at start.

Thank You very much!

Hi! Nikos! I would also like to order this plate from you!

Hi Nikos,

I’m having a similar problem and I’m interested to purchase the metal part from you. can you please email me back.

Hello Nikos,

I have two projectors with this problem. We repair projectors every 3 months. I really need your help.

write me please, waiting for your letter

Thank you very much Nikos for your work and special thanks for the video!!!

I never thought I could figure out and assemble such a complicated device by myself 🙂 Everything works like Swiss clockwork!

My Wemax Pro was working fine until yesterday. Till date I had only used my Amazon Firestick on it and everything was fine. I plugged in a USB drive yesterday and suddenly it went bad. Now every time I start it up it projects a black and white chessboard image for about 5 seconds and then turns off itself.

I dont know how to fix this. There isnt any repair centre here in India.

Please tell me there is a simple way to fix this.

Hi Nikos, thanks for your extensive hardwork to come up with a fix for our Xiaomi/Wemax UST projector. I would lile to purchase 2 pieces. Could you please PM me on the cost including postage to Australia. Thank you!

So a miracle happened. I got a plate and we replaced it ourselves. The problem has been resolved. Joy has no boundaries. Thank you very much. If anyone has any doubts, drop them. I was infinitely grateful. Thank you. By the way, the last video is very informative, I have no experience in parsing such a complex technique, but if you follow the instructions, everything is simple.

Hi I am facing the same issue but I think DMD chip is damaged… can u pls help me… I am not a techie, therefore not sure if can open it myself or not.

Hi White vertical lines also start to appear on my projector. Is the plate still available?

After changing the plate, the videoprojector worked for 4 days without any issue, then it started to auto-reboot non stop, even when it is cold… Do you know if it is due to the thermal pad? Which one do you recommend ?

1) Thickness: 0.2mm? 0.5mm?

2) Model:

– Thermal Grizzly Carbon Carbonaut – 0.2mm (62.5W/m-k) ?

– Innovation Cooling IC Graphite – 0.2mm (35W/m-k) ?

– mod/smart Fujipoly Ultra Extreme XR-m Thermal Pad – 0.5mm (17W/m-k) ?

– Thermal Grizzly Minus Pad 8 – 0.5mm (8W/m-k) ?

hi brother first of all hatsoff to your mind blowing research. i am from india ihave same projector like u showed with same problem model number is MJJGTYDS01FM .can u plz tell if this plate works for this model i would like to buy 1 ,can u plz send pricing details and shipping cost to india to my mail id

rakesh.bujji0@gmail.com

thank you

Hello Sir,

I sent you an email and would like to purchase this part from you. Hope to hear back from you soon! Thank you for your hard work and detective skills tracking down this problem!

Hi,

Is this part suitable for Xgimi RS Pro (medium-throw DLP projector) ?

Nice find Nikos.

I”m doing some research about these new UST projectors (thinking about a new OLED TV or the chinese UST projectors)

Do all the cheaper chinese branded ones have this problem? Could you send me the price of the part with shipping?

Just received the Metal Plate made by Nikos and it works pefectly!!! This Guy is a Genius!!! Thanks again Brother

Hi Nikos,

since you have quite some knowledge about the alpd projectors I was wondering whether you can help me with a different issue. I just bought a xiaomi mija 1S laser projector (the brighter version of the one in your article but identical otherwise). My problem is that I do not get the whole image focussed correctly even though I leveled the projector very carefully (I do not need any trapezoidal correction for a straight picture). If I adjust the focus of one corner, the others will be out of focus. There seems to be a particular imbalance between left an right side but also (to a lesser extend) between top and bottom. Do you know how to adjust/align the lenses to improve focus uniformity? Since the projector is a chineese import to europe I don’t see any help in terms of warranty…

Thanks very much and kind regards

Fabian

Hello there,

I have the exact same projector as you, bought the Xiaomi Mijia 1S in november 2020. It has worked flawlessly since and it has now replaced my TV in the TV/cinema room. I use a fixed frame 100″ inch UST PET-Crystal canvas and the image is mind-blowing.

I bought the replacement part from Nikos without having any of the known symptoms, just in case one day it could happen I would at least have it available at my home to change the part already.

The symptoms you described regarding the focus issue I have that as well, in my case it’s left corner on my canvas – I must add it doesn’t affect the viewing experience at all. I can’t tell at all when viewing content as TV or movies. The only time I notice this is when I’m entering the setup screen for focus or keystone correction screen in settings.

I have my personal opinion about why this issue occurring, it seems like there can be a possibility that a curve on the surface we throw the laser to is to blame. The curve do not need to be big to produce this behavior.

As mentioned earlier in my case I don’t notice this in day to day use when using the projector. Best regards.

Hi,

I have the same problem with my 1S. Have you resolve the issue or have an idea about the problem? 🙁

Thanks

Hi Nikos, I need a metal plate too, do you ship to italy? thanks

Federico, ti interessa vendere il proiettore?

Hi Nikos,

Fantastic work from you! I have the Xiaomi HD UST laser projector (before the 4k version) which has the same issues. Has anyone confirmed if the plate design is the same for both? If so I would like to order one shipped to Australia and happy to pay whatever the costs are to try and get rid of the growing amount of white dots that appear on my screen.

If this is not possible I understand however still want to thank you for your efforts as this is amazing work from you for the projector community. These short throw laser projectors are absolutely amazing and if this white dot issue could be fixed I would be very happy to keep the projector for many years going forward…. Without a long term fix I am hesitant to ever upgrade or buy one again.

John

Hi Nikos,

Thanks for your time and amazing work.

Since you seem to be a a magical wizard on UST (as read on many many forms) would you have a solution concerning the high pitch noie on these VP.

I have the new mija 4K 1S and it has this very annoying sound like coil whine.

I was wondering if you know what caused this, how to solve this ? and if you were actually fixing this devices, I bet a lot of people would be ready to pay for such services

thanks for your help !

Hello Nikos,

i am having the same issue with my new product 4K 1S… I will try to have a new product, but can you tell us if every product will be concern one day or another… ?

Can you send me by email the possibilities and the cost for your replacement plate send to France ?

Kind regards

Thinking about buying that 4k (MJJGTYDS01FM). would you still recommend it?

Would you change the plate from the beginning?

How much would it cost including shipping to Germany?

Jon

Dear Nikos,

Thanks for your amazing post.

May i check with you if my projector problem has the same origin than yours?

My wemax pro does not turn on anymore….

It happened in the past for 2 weeks but miraculously i managed to power on for few months however it happened again….

Last time, i managed to power on randomly and since the picture was no good, i rebooted the system pressing the 2 buttons simultaneously and it worked perfectly for few months…

Now back to no light at all….

Thank you in advance for your comment.

Best,

Henri

I have same problem

Hello. I too have the vertical line issue now. Can you email your contact info to discuss sending my projector to you or getting the plate and costs. Thank you

Hi,

I have the same problem. My projector turns on after 10 minutes and I see lots of white dots in the screen. Will replacing the plate help for the same?? How can I purchase it from you?

Regards

Balaji

Bonjour Nikos,

J’ai moi aussi acheté un vidéoprojecteur Mijia 4k1S il y a 15 jours, et j’ai un défaut d’affichage sur la moitié gauche de l’image projetée (lignes scintillantes ou fixes, comme dupliquées d’autres parties de l’image). C’est très pénible. Le site chinois est très pénible et peu coopératif.

Pouvez-vous m’écrire pour savoir comment et à quelles conditions réparer mon vidéoprojecteur ? J’habite en France. Puis-je vous l’expédier ? Quel serait le coût ?

Merci de votre réponse.

J L

I see there is a slowly growing group of people experiencing the problems of overheating and white lines/dots on their product. I myself has luckily not experienced any trouble with my Xiaomi 1S but as I mentioned earlier I bought the replacement plate in case these issues would arise.

But i can share some information that my seller whom I bought my unit from informed me about.

She told me that Xiaomi recommended that the projector shouldn’t be used more than 5 hours in one sitting. In my case 5 hours use is never a issue – because I at max use it 3 hours a day.

I’m just curious if you guys are using your projectors close to or more than 5 hours every day in one go?

Best regards.

Hello,

I am also experiencing the same issues : slow cold boot, white dots on the edge of the screen, and since yesterday I have a white dot in the middle of the screen (it’s very annoying..) Is it possible to buy that “magical” part that would solve these issues ?

Bruno

For the pb white dot ===} change DMD

https://fr.aliexpress.com/i/4000764881316.html

Hi,

I have the same problem. My projector turns on after 10 minutes and I see lots of white dots in the screen. Will replacing the plate help for the same?? How can I purchase it from you?

Regards

Adel

Tsolas Nikos,

same. can you please let me know if you have made more of these if i can purchese. i don’t have an issue, but i recently ordered this model and want to be prepared. thank you kindly!

Pour le point blanc pb ===} changez DMD

https://fr.aliexpress.com/i/4000764881316.html

merci, but i need the cooling plate. thank you for the link to the chip

I think the slow startup/warped heat sink problem may be endemic.

I didn’t fancy doing it all myself so I sent my 4k Xiaomi to Nikos who has done a superb job replacing it with his parts and startup is back to a few seconds like new.

The white dots are still there but outside the image area and less noticeable. So I would say they are associated with the heat sink problem but not completely rectified by he fix.

Thank you Nikos. Good work.

Hello

Also interested in buying this replacement plate for a xiaomi 1S.

Please let me know by email how to proceed.

Hi Nikos,

I did send you an email. Hopefully your plate wil fix my problem also.

Hello

Would like to buy one plate too. Can you get back to me ?

Regards

Hello Nikos and thank you for your impressive work !

Could you please tell me where I can find/buy the piece of metal ? I’am very interrested, I have the “white dots” problem with my Fengmi 4k pro…

Thank you again for your work and best regards

How to get that part to india

Plz reply

hello Nikos!

can u make this part for me and i will buy it from you?

finally found a solution to the issue as i am in Malaysia and i do not have warranty covered…

Hi Chen,

I am from Malaysia too, at the end did you fix your projector issue?

I have a very strange problem. Its brand new mi 4k 150 ust, left top corner of the screen is slightly stretched and I am unable to adjust it, so 75% of image is perfect, the rest blurry. Its kind of fault, maybe dmd, maybe not. Any suggestions ?

Hello, Nikos!

Please, let me know if I can buy this part from you.

Thank you and have a great day!

Thinking of buying the Fengmi Cinema 3k PRO instead of the Xiaomi 1S. Does anyone get some problems with DMD or cooling plate bending?

I meant 4K, of course (-;

Bonjour y a peu de temps j’ai acheter le projecteur courte focale Xiaomi 4K et depuis una tache blanche circulaire est apparue visible quand l’image est noir ou sombre, j’aimerai savoir pourquoi et la solution pour que ça disparaisse ?

Merci

Cordialement

Hello, Nikos.

I’d like to buy your hand-made plate.

What do I do for you? please reply to me.

Thank you.

I would like to buy your hand-made plate. let me know how much is costs and how to pay you.

would also be interested in knowing how it costs to mail you the projector to be fixed

Hi Nikos

Happy to see you help so many people. I am also facing an issue with my Xiaomi Projector (albeit 1080p not 4k.) The issue is that when I turn it on it doesn’t show me the Mi logo, but straight away shows me a chessboard pattern on screen. It shows the chessboard pattern for a few seconds (7-8s) and then completely turns off.

I am guessing this is a software issue? The image is coming out to be perfectly fine. Any help will be appreciated!

hello, if you have the 4K model then for sure is the plate that cause this problem too.

Hi Nikos,

Just seen what you’ve been through as well as the others.

I’m definitely not the manual guy who could build this piece.

Is there any chance I could order one from you or any links to where I could find the piece already done in perfect quality?

Thanks a million for your answer

Hi,

Looking to purchase 1 of your Projector savers.

Have also used the email on your web page.

Cheers

David

Hey, can you tell me how to buy this plate please?

Good Nikos. I have the Xiaomi mijia 4k 1s but there are some spots in one corner (in dark scenes) and I don’t know if it is the chip that is defective or dirt or dust on the same chip. How much could it cost me if I sent it to you for repair? Is the dmd chip of the 1s the same as Xiaomi’s first 4k model? Many thanks.

Hi Nikolas,

may i have ur contact so i could order this metal part from you?

Hello Nikolas,

Can I order this metal part from you?

Thank you.

Is not really related about he topic. But I wonder if someone could please help me out, I have a xiaomi “rainman” that was working perfectly fine, but I few days ago I decided to turn it on but it was not even turning on the LEDs and not showing images. I went into a technical assistance to check if the power supply or the fuse were burn, but he checked everything it was fine but my projector is not turning on, does anyone had experienced that before? Looking for help, Thanks!

Hello! I wrote you a letter by mail! I want to buy your invention! Thank! Scherstuksergej@yandex.ru

Hi. What chip is installed in this projector? What is the name of the dmd chip hd 5000 marking?

hi Nico,

Is it Possible i buy the cnc plate for 20 pcs?

Alfredovicky7@gmail.com

Regards,

Vicky

Hey, I received the block here in Australia within 15 days. Nikos was helpful with the purchase and responded well. The finishing of the product is really good. Hopefully it fixes my issue. The parcel was stuck stuck for a while with ELTA and Nikos wasn’t replying, but I guess he was busy. Overall happy with the product and the transaction. Keep up the good work.

You are welcome my friend!

Hi Nikos,

Can I order this special plate?Please let me know cost and shipping to Australia.

All the best to you.

Joseph

Have you tried titanium plate?

will this fit a Model: Xiaomi MJJGTYDS01FM 4k UST Laser Projector

Hi Nikos

I’m thinking of buying a Xiaomi MJJGTYDS01FM which works fine for the first 5 minutes and then has image distortion on half of the picture. Do you think it’s related to the bending plate ( I can send you images of the distortion if this helps)? If yes I’m interested in buying one from you.

This repair operation seems intense but the videos Nikos provides help a huge amount and you can probably get things done in an hour ish. I got mine all back together and surprise! The projector now boots up super fast like day one. Now if I could just get it to talk nicely between my apple TV and Samsung Soundbar 🙂

I’d attach a few photos but they just confirm what Nikos has already shown. It can seem overwhelming the amount of things you have to disconnect and reconnect, but take it slow, don’t force anything too much and it will all work out well. It is amazing how bent this piece of metal is. No wonder the display chip was having issues.

Hi,

Does anyone know if a replacement I/O card can be purchased, if so, how much for?

This is for a Wemax One Pro.

Many thanks in advance

Mike

Hi guys, love the page. I have Xioami 4K projector. Unfortunately it has started to shutdown automatically after the Adroid is launched, any suggestions? Thank you for any advice.

P.S. It’s under warranty, but I live in 3rd world and not going back soon to Europe, so it will be good to try to repair it.

I bought a faulty Xiaomi MJJGTYDS01FM and I asked my very talented nephew to design the plate in a 3D package and I’ve just ordered one. I should get it in a couple of weeks and I’ll let you know if it fixes the problem. Fingers crossed.

Hi Nikos,

Great work you have done here.

Like others, I have the same problem :).

I’ve just sent you an email to buy the plate.

Hi there,

I plan to buy same projector so I thinK I will buy spare plate just in case. How can I buy the plate?

My other alternative is Vava 4K. It is considerable more expensive but they look similar. I wonder if it suffers the same problem or it is just a better buy than Chinese models?

Best Regards.

Hi NM, which one did you go for ? and did you ever get any answer if the Vava one suffers from the same problem ? Cheers mate

no, i have never repair a VAVA, but this does noy mean something as Xiaomi sales are much much bigger than VAVA.

Hi Nikos, I have a VAVA 4K Short throw. and it has started to show the exact same problem. Vertical lines on the right half. Do you think it is the same plate? Any help is really really appreciated.

Would you kindly reply to my email id?

Hello Nikos,

Do you still sell the plates? If yes, can you contact me via email.

Thank you

Best Regards

Hi

Can anyone help me my project stop visual every 10/12 minutes but sound is working. Xiaomi 4k lazer .

I bought the plate from Nikos and replaced it myself referring to the video posted in this forum. It works like a charm!! After replacing the plate, my projector starts in like less than 15 seconds (which earlier took 5 mintues!) All the white grains in the picture is gone.. and the projector working as new! Nikos, you are the best!

For all the folks who are looking to buy from US plan for a month to receive the part due to shipping delays. I live in Phoenix, US and the part took almost a month to reach here. Nikos followed up with the post office and provided shipping updates that were not available online.

Thanks again!!

Hello. I wrote to the mail, but there is no answer. Can’t buy the plate anymore?

Bonjour, je souhaiterai vous acheter la plaque,

pouvez-vous me donner les démarches à suivre

et le mode de paiement sachant que j’habite en France.

Merci

Hi nikos I am also looking for the plate, happy to buy it from you !

Best

Hello Nikos,

I got exactly the same problem with my Mijia.

I would like to order a plate from you. Can you please contact me in order to arrange the details?

Are these plates still available? My Xiaomi 4K is in desperate need for a fix? Please contact.

Quick follow-up here! A great fix to this projector – before my projector just overheated and acted odd. Now it starts immediately and stays on without any hiccups. Great work Nikos!

Hi nikos how are you ? my mijia 4k facing the same issues, is it possible to buy the plates ?

Bonjour

je m’ajoute a la liste des lignes blanches, projecteur achété en mars sur bangood,lignes blanches depuis envrion 1 mois

@ Nikos je suis preneur des modalités d’acahnt de la pièce

Merci

Marc

Hello Nikos, My Xiaomi 4K as started to show some white dots. Do you still sell the plates? how to buy the plate from you ? im in france by the way.

Hi Nikos!

Definitely need one of your metal plate!.. Any chance to get one please?

Thanks a lot!

Hi. Are these plates still available? My Xiaomi is in need for a fix..please contact me when you have the time.

Regards

Sasha

Hello Nikos

I’m having the same problem on my fengmi 4k cinema projector. Would it be possible to order the part and send it to Brazil? What is the process? Sorry for the English, I’m using google translator. Thank you very much.

Hi Nikos,

I sent you an email. I would like to purchase the metal part. Can you please reply.

Thanks

Ajeesh

HI Nikos Tsolas,

I bought brand new Xiaomi 4k projector after 2 days while watching 4K movies it shut down.

Now, the projector starts with just standby white light the fan spins at high speed and shuts down without any visual or warning.

Is it possible the plate may be at fault here?

Thanks

Pankaj

I have the same issue happen to my Xiaomi 4K Projector, Do you have any solution for that?

Have the same issue with mine since almost a year ago and didn’t fix it, projectors starts with no screen, fans on maximum and remote doesn’t work. I found a company that fixes Xiaomi projectors and sent it to them and after a diagnose they told me that I have a software problem with BIOS chip and they can’t fix it.

Salut Nikos ,

J’ai le Xiaomi 1S 4K.Vais-je en avoir besoin?

Reynald

I have an issue where during warmup picture turns into black and white with some white dots?

If it helps and if you could send replacement part – are you sending it from EU our outside of EU?

Hello Nikos, just to report that i replaced the metal plate with the one you sent exactly one year ago on my Xiaomi 4k… and still up and running like the first time i repaired it !

Greeting from Mexico!

take care!

Greetings from Greece my friend!Mine is runninmg liek new too!

I have a Xiaomi Mi Laser Ultra-Short Throw Projector showing some minor dots and vertical lines they are not as promonebt but there. How can i get the plate?

Hello Nikos, My Xiaomi 4K as started to show some white lines. Do you still sell the plates? how to buy the plate from you ? im in berlin . please mail me for more. thanx

Hi Nikos ,

I have sent u an email to request the purchase of the metal plate !! I have try to repair many times by it last only for a couple of months , I really need this metal plate. Thanks for your assistance !!

Hello Nikos,

I got exactly the same problem with my Mijia Projector.

I would like to order a plate from you.

Could you please contact me in order to arrange the details?

I would like to order one of these metal plates as well.

Hi Nikos,

you say with the latest editions, it seems that they have solved the problem. Did they contact you? 😉

I just wanted to thank you again for your hard work on that.

I changed the plate a year ago and my projector still works fine and looks very nice with the Celexon screen.

Greetings from Germany

Hi, how much si the cost of the new plate ?

I need 3, i m from Argentina.

Greetings

Hi Nikos,

I would love to order a metal plate to germany please.

Can you please be so kind as to get intouch with me.

Hi Nikos, I want to thank you for the perfect work on projectors. My respect and great tribute for the effort and time invested. I would be interested in buying a holder for a DMD chip. I live in the EU.

My projector is marked Model No: MJJGTYGS01FM

Thank you for your reply and I wish you a beautiful Christmas

Hi Nikos,

I’d like to purchase one of the plates and have it shipped over to Australia. Could you help with placing the order please?

Hello,

i have a lot of problems on my xiaomi 1s, i want to order one plate please.

thanks and merry Christmas

Hi Nikos,

I would love to order a metal plate to Taiwan please.

Can you please be so kind as to get intouch with me.

Nikos, thank you very much for the pressure plate. The exchange went smoothly. The projector makes the owner happy for the second week. My compliments and thank you very much for making this page. It could easily be used in schools as an introduction to the issue of projectors. Well thank you , from Slovakia.

Hi Nikos,

I’m interested in buying the pressure plate. Could you please help me with the process?

Hi Nikos,

I also need one plate. I am from Germany. How to get in touch ?

Greetings Zoran

Hi guys,

have any body a romdump for l176fcn fengmi?

Hello,

I would like to order you one plate.

I am from France.

I sent you 2 emails but no answers.

Could you help me or tell me where to buy a replacement plate ?

Thank you.

Hi Nikos,

I have a wemax one pro and it has been constantly auto shutting down due to overheating error. I suppose it’s facing the problem you described. Can I purchase the replacement plate frok you to solve the problem. Seek ur help with my repairs. Thanks so much!

was fixed?

Hi

Does anybody know where to buy spar parts – DMD chip and DMD cable (connector)? I have a Fengmi projector 4K cinema laser projector 2000 ANSI. ¨

Thank you.

Hi Nikos,

Could I also purchase one plate from you?

I’m located at CA 91030

Many thanks.

Hey Nikos,

Woah the chat exploded literally.

Still in the game to sell the spare plates?

Owner of a first gen xiaomi mijia 4k projector and started to get the startup- and dots problems.

Please get in touch with me.

Thanks a lot

Hi Nikos,

I need a plate for me Xiaomi 4k 1s proyector

Please get in touch with me

Tanks

Hi I would like to purchase the metal plate too, could you get in touch with me too? Same mijia model as yours. Thanks

Hi Nikos,

I would like to purchase the plate for my wemax 4K projector. Please get in touch with me.

Thank you,

Johnny

Hi Nikos.

I just bought one of these projectos used.

Mine is working ok and boots up fast.

Do you know if there was any revision of these projectors as to resolve this matter?

If not how do i get one metal plate from you so that if and when a problem ocours i can replace it immideatly.

Best regards.

Hi Nikos,